7 Steps to Successful Business Process Optimization

Every business runs on processes, but not all methods work as well as they should. Missed deadlines, slow approvals, and repeated errors come from workflows that are outdated or poorly designed.

These inefficiencies hold back growth, even when the demand and potential are there.

A business process optimization strategy involves identifying these weak points and redesigning them to achieve better performance. When you take a structured approach, you can improve business efficiency, lower costs, and give employees more time to focus on meaningful work.

In this article, we will explore the benefits of business process optimization and the proven techniques for making processes faster and more reliable.

Signs Your Business Needs Optimized Processes#

Not every organization realizes it’s time to change until problems pile up. Here are the most common signs that your company is ready for process improvement:

Repeated Errors and Bottlenecks#

If teams keep running into the same problems, it’s a red flag. Errors in invoices, delays in approvals, or missing steps in projects all point to broken workflows in your existing processes.

Bottlenecks cause tasks to stall at one stage, which leaves employees waiting for input or approval that could have been automated or simplified. These are a few cases of identifying inefficiencies that affect process completion and slow down business operations.

For example, the sales team may wait days for contract approval because the process requires manual review by multiple managers.

Companies such as Toyota and Ford provide real-life examples of how removing bottlenecks through standardization and automation drives measurable gains. When you redesign the workflow and use process mapping, approvals can happen within hours.

Too Much Manual Work#

Activities like copying data between systems, preparing the same reports each week, or manually scheduling meetings consume valuable time that could be spent on higher-value work.

Errors in invoices, purchase orders, or customer records can cause delays, compliance issues, and added costs.

Business process automation helps reduce this burden by introducing digital workflows that support streamlined operations and more efficient processes.

For example, approval requests can be routed automatically to the right manager, and reports can be generated directly from integrated systems instead of being compiled by hand.

In customer-facing workflows, a customer service chatbot can handle routine inquiries, schedule meetings, and provide updates instantly. This reduces the repetitive workload on employees and improves the speed and accuracy of the service supplied to customers.

Big retailers like Amazon and Shopify offer a few real-life examples of how automating repetitive support tasks improves accuracy and allows staff to enhance productivity by focusing on strategic work.

Long Approval Cycles#

Slow approvals occur when too many people are involved in decision-making or when documents are passed manually from one department to another. This creates delays that affect not only internal productivity but also customer satisfaction.

Extended approval cycles can hurt profitability. For example, if purchase orders or invoices take weeks to clear, suppliers may experience delays in payment, and customers may face longer delivery times.

Optimization shortens approval times by reducing unnecessary steps and introducing automated workflows. Instead of requiring multiple signatures for every request, rules can be set so that only key processes or exceptions go to higher management.

Digital approval systems send notifications instantly and allow managers to review and approve requests on any device. Tracking KPIs in this area confirms execution success and highlights where resource allocation can be improved. The right teams can also focus on the highest-value activities.

Outdated Technology or Legacy Systems#

Legacy tools may have worked in the past, but as your business needs change, they can create complex processes that reduce operational efficiency.

Common issues include slow performance, limited integrations, and a lack of automation features. These gaps force employees to work around the system rather than with it, adding unnecessary delays to daily operations.

Disconnected systems are also a major problem. When platforms cannot communicate with each other, employees end up entering the same data into multiple applications, which increases the risk of errors.

Low Employee Morale and High Frustration#

If your staff spends hours on repetitive manual work or struggles with outdated tools, morale will eventually decline. Over time, this frustration can lead to disengagement and reduced productivity.

Poor processes also create stress. Employees forced to handle customer complaints caused by delays often feel responsible for problems outside their control.

A Gallup study shows that employee engagement fell to 21% in 2024, with managers seeing the sharpest decline. This highlights the need to implement business process optimization initiatives that address core frustrations.

When you focus on improving business processes, you create an environment where staff can concentrate on value-driven tasks rather than fighting inefficiencies.

Customer Complaints Rising#

When processes are inefficient, customers notice, and they are most likely to choose competitors who can serve them faster. This is where the benefits of process optimization are most visible.

Research shows that most customers will not tolerate repeated mistakes. According to PwC, 32% of customers will walk away from a brand they previously liked after just one poor interaction.

It shows how damaging poor existing business processes can be. Even a single weak point in your operations can lead to customer loss and reduced revenue.

One of the most effective ways to address complaints is by reducing wait times. Ecommerce AI agents can provide instant answers to common questions, give real-time order updates, and route complex requests to the right team.

7 Steps to Effective Business Process Optimization#

Without a specific approach, you risk making changes that do not solve underlying issues. Below are the steps you can follow to implement business process optimization systematically.

Step #1: Identify Processes That Need Improvement#

Not every particular process requires immediate attention, so it is important to focus on the ones that have the highest impact on productivity and customer satisfaction.

You can start by examining manual tasks that consume too much time. For example, manual data entry, repeated approval requests, or duplicate reporting can signal inefficiencies.

You should also look for current processes that create frequent employee frustration or generate recurring customer complaints. These are usually strong indicators that improvement is needed.

It is also helpful to gather input directly from employees. Since they work with multiple processes daily, they can provide valuable insights into where to identify bottlenecks.

A structured survey or team workshop can uncover hidden inefficiencies that leadership may overlook.

Step #2: Map Current Workflows#

Once you identify the processes that require improvement, it's time to map out how those processes currently work. This step creates a visual representation of the workflow, which makes it easier to see where gaps or unnecessary steps exist.

Start by documenting every stage of the process from beginning to end. Include who is responsible for each step, the tools or systems used, and the order of tasks. It can be done using flowcharts, swimlane diagrams, or process documentation software.

While mapping, pay close attention to areas where tasks are handed off between teams or systems. These transition points are often where delays occur.

For example, an approval process that passes through process owners may look reasonable on paper, but may create days of waiting in practice.

Make sure to note where technology is already involved and where manual work is still used. If employees are entering the same data into multiple systems, that duplication will stand out in the map.

Step #3: Analyze Bottlenecks and Inefficiencies#

This is where you take the visual representation of the process and perform workflow analysis to evaluate it closely for delays and wasted effort.

A bottleneck typically appears where work piles up faster than it can be handled. For example, a single manager approving every purchase order may cause delays that ripple through an entire department.

Inefficiencies may also show up in the form of duplicated tasks, unnecessary reporting, or manual work that could be automated. Once you identify areas of weakness, you can see the steps that slow down productivity and raise operational costs.

Quantitative data is key to this process analysis. You need to review metrics such as turnaround times, error rates, and customer complaints tied to specific processes.

If support tickets take longer than expected because of repeated handoffs, the data will highlight the delay. At the same time, qualitative feedback from employees can reveal where frustration occurs, such as manual entries or excessive approvals.

This stage is also an opportunity to consider process optimization tools, such as a workflow automation platform, which can help in automating repetitive tasks.

Step #4: Redesign Processes for Simplicity#

Many existing business processes grow over time as new checks, forms, or approvals are added. These layers may have been useful at some point, but often they only slow things down.

As you redesign, focus on optimizing business processes by cutting out tasks that do not add measurable value.

Next, you need to restructure handoffs between people and departments. Every handoff is a chance for delay, so reducing them speeds up the entire process.

For example, instead of routing every document through three managers, create role-based rules where only exceptions require higher approval.

Technology can also play a strong role in redesign. You may consider process optimization tools that streamline workflows and support business process management. For customer-facing workflows, introducing AI-powered customer support can simplify how inquiries are managed.

The chatbot handles standard questions, routes complex cases, and updates systems automatically, which shortens the process and frees staff to focus on higher-value work.

Step #5: Implement Technology and Automation#

Technology should not replace your processes, but rather support them by improving business processes, reducing errors, and delivering optimal efficiency.

Start by identifying the core processes that consume the most time and resources. Approvals, reporting, and scheduling are common examples. These can often be automated with project management systems or integrated software.

Automation also improves consistency. Manual work is prone to human error, while digital workflows execute tasks the same way every time. This leads to fewer mistakes, faster results, and stronger compliance with company policies.

Artificial intelligence is also becoming a practical part of process optimization. An ecommerce chatbot can handle incoming customer queries, provide instant answers, and route requests to the right department when needed.

This reduces pressure on support teams and improves response times, which is critical for customer satisfaction. Similarly, AI-driven analytics tools can monitor workflows and highlight new areas for improvement, which gives you real-time visibility into operations.

When introducing technology, focus on integration with existing systems. Tools should connect seamlessly with your CRM, ERP, or communication platforms so employees do not have to manage multiple disconnected applications.

Step #6: Train Teams and Communicate Changes#

No matter how well you redesign or automate a workflow, business process optimization will not succeed unless your employees understand and adopt the changes. Training and communication are key to making new processes work in practice.

Employees are more likely to accept updates when they see the benefits of process optimization for reducing manual effort and addressing customer demands. You can provide structured training sessions, documentation, or workshops that explain changes clearly.

Feedback loops are equally important. When staff can raise concerns, they become active participants in process optimization projects. This supports adoption and identifies small refinements for continuous process improvements.

Step #7: Monitor, Measure, and Continuously Improve#

The final stage is to treat improvement as a continuous process, not a one-time fix.

You need to set measurable goals through key performance indicators (KPIs) that track turnaround times, process efficiency, and improved customer satisfaction. Monitoring results confirm process execution success and highlight where further refinements are needed.

For example, if an approval process was redesigned to cut delays, monitoring the average turnaround time will confirm if the change is successful.

Regular reviews should include both process owners and employees. With process analysis and tools that track process data, you can identify new gaps and improve processes over time.

Popular Business Process Optimization Techniques#

When applying business process optimization, there are several structured approaches you can follow. Each has been widely used across industries, but the results depend on your business environment, leadership support, and how changes are managed.

Lean Six Sigma#

Lean Six Sigma combines two approaches: Lean, which focuses on reducing waste, and Six Sigma, which focuses on reducing variation and errors.

Many organizations use it as part of their optimization process to reduce costs and improve quality in both manufacturing and service operations.

Studies have shown that companies applying Lean Six Sigma can lower operating costs, sometimes by as much as 25–30%, though actual results vary by industry and the maturity of optimization efforts.

Total Quality Management#

Total quality management (TQM) is a long-term management philosophy where everyone in the company is involved in managing processes and focusing on continuous improvement.

The approach emphasizes customer satisfaction, consistency, and aligning with broader strategic initiatives.

While results may take time, businesses that successfully adopt TQM often report stronger product reliability and higher customer satisfaction, which creates a durable competitive advantage.

Kaizen (Continuous Improvement)#

Kaizen is a Japanese approach that focuses on small, continuous improvements over time.

Instead of waiting for major projects, businesses using Kaizen make gradual adjustments that add up to significant progress. It is effective in building employee involvement, as staff at all levels are encouraged to suggest changes that improve daily work.

Business Process Reengineering#

Business process reengineering (BPR) takes a more radical approach by redesigning processes from the ground up. When done well, it can deliver large improvements in speed and cost reduction.

However, BPR also comes with a higher risk because it often requires change management, new systems, and cultural alignment.

Automation and Digital Tools#

Technology plays an important role in improving business processes. AI automation reduces manual effort and boosts accuracy in tasks like approvals, reporting, and customer support.

AI agent tools can help manage customer interactions, answer common questions instantly, and route complex requests to staff.

These tools improve response times and reduce the workload on employees. However, success depends on choosing the right tools and integrating them properly with existing systems.

Automate Your Way to Better Customer Experiences—Try Denser!#

The real barrier to growth isn’t lack of effort but inefficient processes that drain time and resources. If manual tasks and customer complaints weigh down your business, it’s time to optimize.

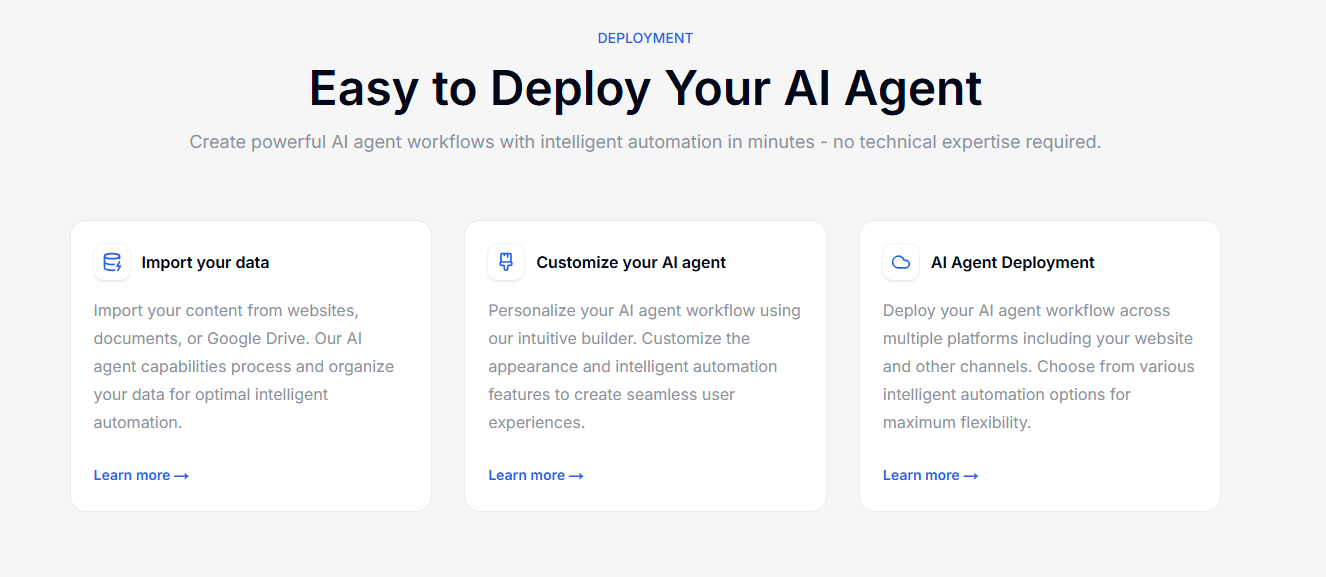

Denser provides the tools to turn broken workflows into scalable systems that save money and improve performance. With an AI-driven chatbot platform, repetitive tasks like customer FAQs, ticket routing, and scheduling no longer overwhelm your team.

Instead, employees focus on higher-value work while Denser manages the everyday interactions that keep your business moving. You'll deliver faster approvals, and customers will receive the quick, reliable service they expect.

Short-term wins are important, but process optimization delivers lasting stability and growth. Denser helps you achieve that by combining automation, real-time insights, and seamless integration with the systems you already use.

Start optimizing today with Denser and create processes that support profitability and long-term success. Request a product demo or sign up for a free trial now!

FAQs About Business Process Optimization#

What is an example of business optimization?#

A common example of business optimization is improving the way a company handles inventory. Switching from manual tracking to an automated inventory management system can reduce stock shortages, avoid over-ordering, and improve order fulfillment speed.

What is an example of process optimization?#

One of the most practical business process optimization examples is redesigning customer support workflows.

Instead of routing every inquiry through a human agent, you can introduce a chatbot to respond instantly to routine questions. Human agents then focus on more complex issues, which helps you increase customer satisfaction.

What are the steps in process optimization?#

The steps typically followed in business process optimization include:

- Identify processes that require improvement

- Map current workflows to understand how they operate

- Analyze bottlenecks and inefficiencies

- Redesign processes for simplicity

- Implement technology and automation to support changes

- Train employees and communicate updates

- Monitor performance and continuously improve

This optimization process is not one-and-done. It’s a continuous process that you repeat as needs evolve. Tools such as process mining to track performance data and guide adjustments promote improved efficiency.

What are the four types of business processes?#

Business processes are usually divided into four main categories:

- Operational processes: Core activities that deliver value to customers, such as production, sales, or service delivery

- Supporting processes: Internal processes that enable operations, such as HR, IT, or payroll

- Management processes: Processes that guide planning, monitoring, and control, such as budgeting or strategic planning

- Innovation processes: Processes related to product development, research, and adapting to market changes

These categories highlight where optimization can have the biggest effect to increase efficiency, improve resource utilization, and strengthen long-term productivity.